Quick sustainability facts

This year we hope to save

6M

Litres

of water

727

M

BTU’s

of energy

Every run of the still we save

7k

Litres

of water

850k

BTU’s

of energy transferred to the hotel

Sustainability

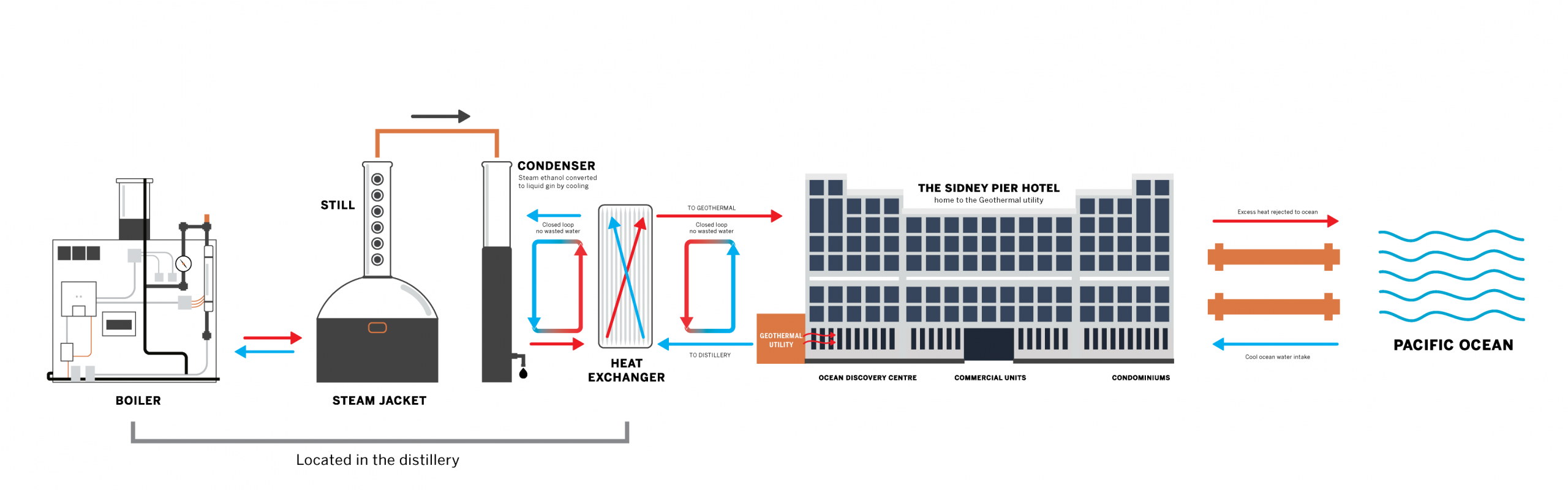

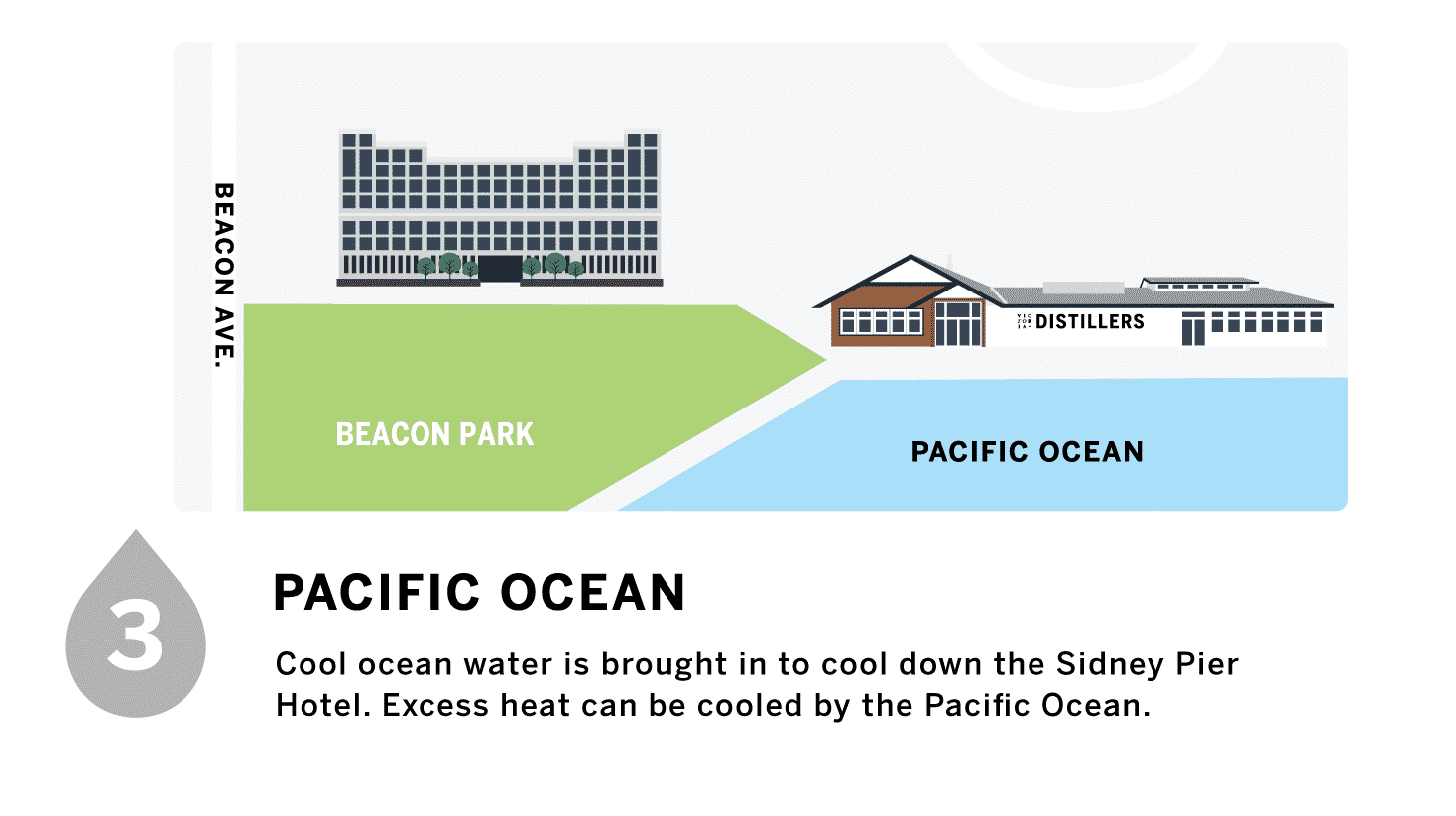

At Victoria Distillers, we pride ourselves on taking steps to reduce our environmental impact where possible. In 2016, to accommodate our growing business, Victoria Spirits, was acquired by the current owners and moved to a larger waterfront location where it became Victoria Distillers. The location was a strategic move that not only increased production capabilities but also would allow for more sustainable distilling practices. The distillery’s owners have several properties in the area, including the Sidney Pier Hotel next door. The hotel was built with a unique geothermal system, which they were able to connect to the distillery.

In the process of distillation, heat is used to separate alcohol, and cold water runs through a condensing chamber to convert alcohol vapours back into a liquid – our spirits. To help mitigate the traditional waste of energy that can occur during distillation, we have created a closed-loop system between our stills and the geothermal system. This process saves energy through the recapturing of heat from hot water, which is used to warm the hotel throughout the colder months. It also supplies cold water for our condensers by sending the cooled water back to the distillery to be used again. This saves roughly 7,000 litres or 1,500 gallons of water and transfers approximately 850,000 BTU’s of energy to the hotel with every run of the still. This year we are expecting to save about 6,000,000 litres or 1,284,000 gallons of precious water and 727,600,000 BTU’s. In 2019, our distillery was awarded an EcoStar award for its water stewardship in addition to achieving the Vancouver Island Green Business standard.

Sustainable practices in distillery operations take many forms and we recognize that doing just one thing is not enough. In addition to our geothermal system, we have implemented significant recycling programs and have eliminated the use of plastic bags or straws in our tasting room. An Environmental Committee we call our ‘Green Team’ meets monthly to evaluate and monitor our eco-initiatives. Through meetings with corporate sustainability experts to shed light on other areas in which we can improve, our team continues to discover and implement new methods to reduce our environmental footprint.

Geothermal Breakdown Path

Sustainable Distilling Process

Scroll through to learn more about our unique process. Click the dots on the graphic for additional information about each step.